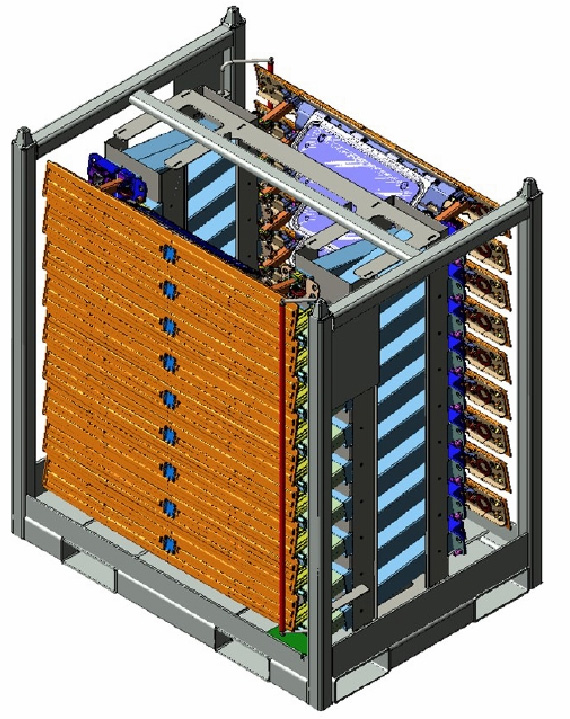

MISSION:

MAX OUT your QPC

MAXIMIZE the density and efficiency of your fleet

MINAMIZE number of racks, Real estate, Handling, and shipping costs

With your part math data, we design the rack

Prototype turned around

in 48 Hrs. on most designs

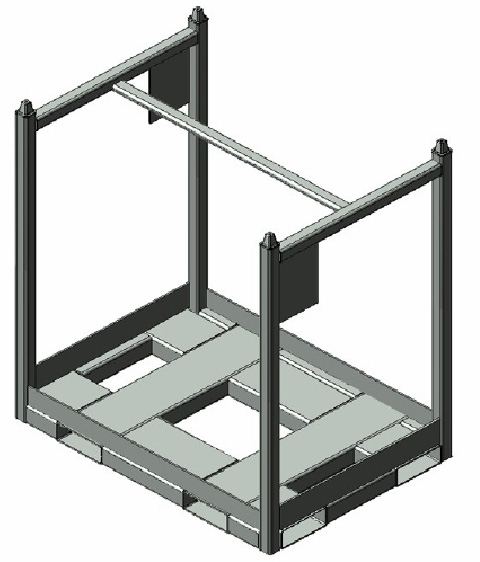

STATE OF THE ART DESIGN

- The frame is the only component that is completely welded.

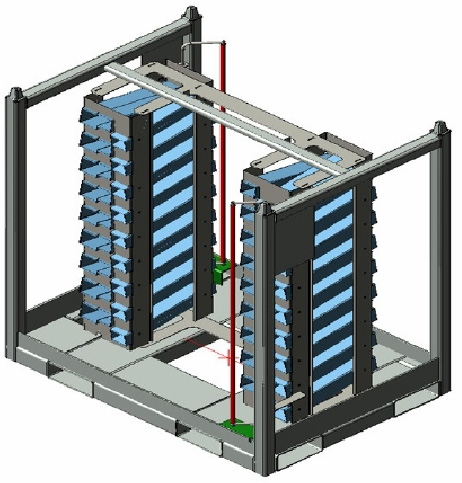

- The Internal parts are a metal laser sub assembly.

- Laser cut and precision locked together

Designing our racks this way...

- Allows for Precision throughout manufacturing

- Frames can be used again for future programs

- Less welding! Less expensive to fabricate!!!!

- Reduce the risk of variance caused by welding

- Assembly is exactly the same each time

- Repairs are easy and cost effective

EXISTING PROGRAM EXAMPLE

With your part math data and a list of requirements, we were able to customize a more efficient rack design than the existing.

CURRENT RACK:

In use for 5 years, holds: 16 parts/rack

Requested Fleet size: 1113 racks

OUR DESIGN:

Holds: 18 parts/rack

Requires a fleet size of only: 990 Racks!

REDUCING FLEET SIZE BY 20%

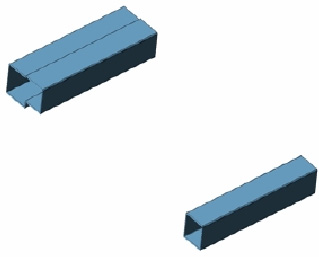

By Designing Custom Dunnage Extrusions we are able to

- Minimize wasted space and maximize part density

- Provide a more secure dunnage application that will

- Better protect parts in transit

PROFESSIONAL DESIGN

WE Will MAXIMIZE the density of your fleet and REDUCE shipping costs by as much as 33% in many cases!

Using a CAD modeling program that can convert any math data and provide instant 3D modeling.

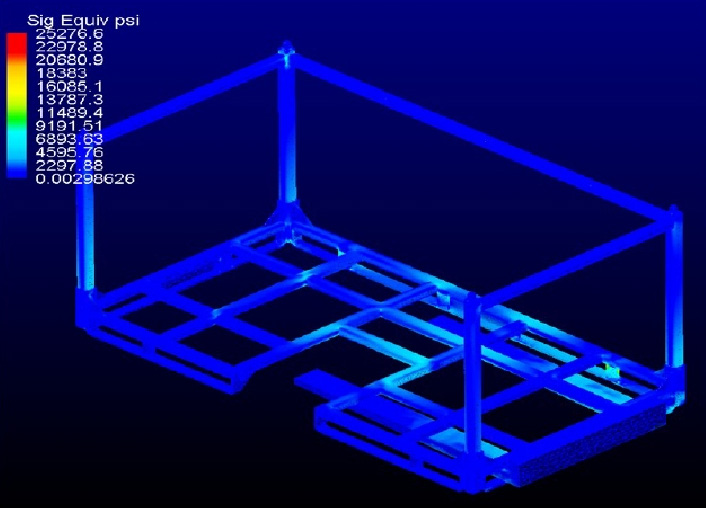

Our Professional prototyping can preform FINITE ELEMENT ANALYSIS

- Static Strain & Stress

- Buckling Analysis

- Model Analysis

- Thermal Analysis

- Dynamic Analysis

Allows us to verify any design will preform to clients specifications without failure prior to manufacturing.

Used for New product design and Existing product refinement.

IN HOUSE PROCESSING CAPABILITIES

- CNC Cutting

- CNC Water Jet Cutting

- CNC Laser

- CNC lathe

- CNC Forming

- CNC Machining

- CNC Shearing

- CNC Punching

- Air Dry and Powder

- Ccoat paint finish